Blogs

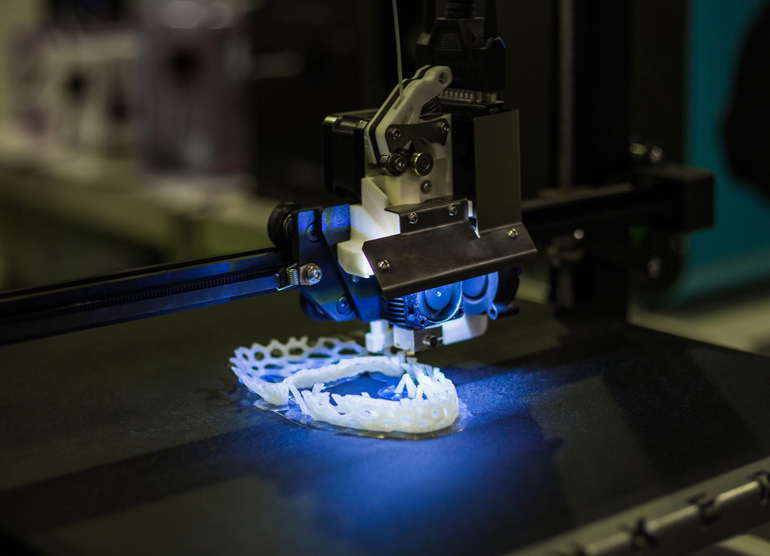

Due to their multiple advantages, cutting-edge 3D Printing Services in India are now being used in various sectors and applications. One of the best uses for 3D printing in the metal industry is rapid prototyping. Using traditional methods to create a prototype is a costly and time-consuming process. With a high-quality and shorter lead time, 3D printing facilitates new product development. You can obtain innovative engineering and design solutions with a metal prototype using 3d printing, which helps get beyond the constraints imposed by many conventional production technologies.

Let’s explore the benefits of using metal 3D printing for rapid prototyping.

Solid 3D items are created using rapid metal prototyping technology. When required, one can change the object design with a CAD model. The CAD file is then used to build objects made of metal powder. Prototypes are made in days or weeks. Many prototype techniques are used, like SLM, SLA, SLS, DMLS, FDM, MJF, and others. These processes have specific advantages that make it easier to produce prototypes according to the requirement of various sectors.

Benefits of using metal 3D printing for rapid prototypes.

- Offers Flexibility in design

We can create a wide range of objects using 3D printing, from simple to complex shapes. You can develop any design from scratch with 3D printing, get a clear visualization, and edit the 3D model whenever possible. Rapid prototyping with 3D printing is practical because each iteration doesn't require the formation of a full mold. A prototype that meets your requirements for the finished product is obtained after several iterations.

- Metal 3D printing Reduced lead time

Rapid prototyping, as the name implies, is a rapid process that uses less time for production than

traditional manufacturing techniques. It enables the creation of numerous iterations in a remarkably short time and the early validation of the design.

- It is cost-effective

3D printing for metal prototypes has advantages that reduce the cost of product production. It is a quick procedure that facilitates small batch production by eliminating the requirement for tools and dies. Also, before starting the actual manufacturing, you can receive a prototype of the desired material and evaluate its feasibility and performance. Moreover, as it uses additive manufacturing, which involves adding materials to create the final product, there is minimal wastage of material.

- Offers Parts consolidation

Using 3D printing for metal prototyping makes it simple to manufacture intricate parts. Additionally, it helps in minimizing the number of components. This significant development has paved the way for improved products and components for automotive, aerospace, and various other industries.

- Shorter time to market

With 3D metal prototyping, a product can be produced in a shorter span of time. Companies can

therefore release new products more quickly. A faster launch signifies a greater chance of success prediction.

Innovae3D offers on-demand 3D Metal printing in India. We work on 3D printing projects, from ideas to printing and post-processing, comprising design, development, and analysis.

The production facility of Innovae3D is well-equipped to handle our customers 3D printing requirements across various industries. Our skilled designers quickly produce the most complex ideas and prototypes. We assist you in making the most profit and provide the fastest turnaround time for 3D Printing Services in India.

Please contact us for 3D Printing Services in Pune, Rapid Prototyping Services in India.