Blogs

NASA has built a 3D printer at the International Space Station that is adopted by the astronauts to custom-built tools without the need for them to fly into space. Amazing, isn’t it?

This innovative technology has even stormed the automotive sector and has led to a paradigm shift in the manufacturing of automobiles.

Let us dig deep into this exciting technology and know what makes its exciting!

What is 3D Printing?

3D printing is a manufacturing process used to create a physical 3D object from a digital model. The 3D object can be printed using different materials according to the printer such as alloys, ceramic, concrete, metals, paper, plastic, polymer, rubber, etc. The printing process varies according to the material, along with the efficiency of printing changes. 3D printing has become an important manufacturing technology with wide application across the globe.

Applications of 3D Printing

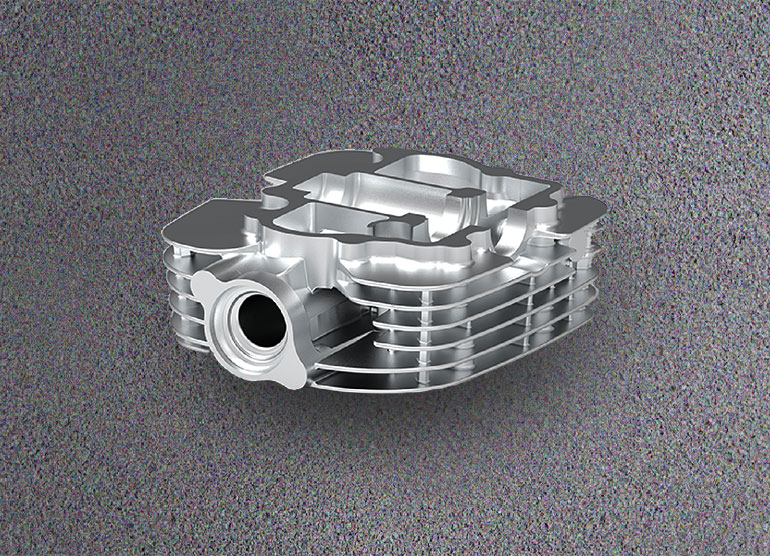

The applications of metal 3D printing in the automotive industry are increasing day by day. We usually see the 3D printers at schools, colleges, and stationeries, but it has made a significant impact across the automotive industry. From prototypes to complete parts, it is being adopted extensively. Metal 3D printing automotive parts can be ducts, interiors, bellows, and many more.

Traditional manufacturing includes molds which make the process quite expensive; while working on a prototype, it is not the best option. That’s when the makers practice metal 3D printing in automotive and the parts for prototypes are made with different options at a much lower operating cost. The manufacturers can test the parts, do changes, or replace them and go with the best solutions while saving them money and further improving productivity.

Advantages of Metal 3D Printing in Automotive Industry

Today, 3D printing is getting recognized across several industrial applications and many automotive industries are adopting it owing to their several advantages. Here are some:

-

Fast prototyping

-

Decreased turnaround time

-

Saves cost

-

Decreased wastage

-

Less plastic waste

-

Easier to replace spare parts

Materials used in 3D Printing in Automotive

Automotive is a challenging sector which requires adapted materials for 3D printing. Here are some suitable materials:

-

Stainless Steel

-

Titanium

-

Tool Steels

-

Inconel 625

Essential Manufacturing Tools

Metal 3D printing automotive parts get the attention, but most of us ignore the 3D printing of tools. Yes, you heard it right; many brands are using innovative technology for tools manufacturing. It does not only reduce cost but also increases efficiency.

Ford has begun to use 3D printing for custom and flexible tools for particular tasks. The skilled workforce can now directly print customized tools and start working. The other major automotive manufacturers such as Volkswagen have further started metal 3D printing in the automotive industry for parts and tools and it proudly claims to have saved around 250,000 Euros in 2017 with the help of 3D printing.

The Road Ahead

The future is something we can never catch in the present, but by analyzing the history and present, we can definitely have a vision about the upcoming technologies. Metal 3D printing in automotive is becoming a big deal and now we can predict some of its upcoming trends.

-

The Revival of the Classics

Many classic engines cannot rule the roads as the spare parts are not being made any longer. However, 3D printing changes this scenario upside down and now we can print the exact part we want and it doesn't have to be manufactured in large quantities. Jaguar and Porsche are some names in the industry who have already been practicing this and now we can see every other company is going to use it. It helps the brand’s legacy and also increases its credibility as the brand is still providing support to the older machines.

-

Better Factory Customization

Customers are always spending money on customizations of their vehicles even to a third party. The makers couldn’t provide it as it would be difficult to provide different parts with conventional manufacturing processes.

Now, metal 3D printing in the automotive industry enables the makers to print smaller and larger components differently but with ease, the makers can now offer vivid customization from the factory itself. This will give each vehicle a personal touch that can be capitalized by the brand.

-

3D Printed Cars

Metal 3D printing in automotive has gone so far that it would not be far when 3D printed cars are a possibility. It enables customers to print the car they want.

Divergent 3D is ready with Blade, a 700 hp car waiting to run the streets. Other companies like LSEV, Strati are also climbing the same ladder.

Though it is not possible now to 3D print a car, we are already living in an era where 3D printing is dominating the automotive sector.

The advancement in technology and the increasing focus on developing specialized micro-factories to produce custom parts is propelling the automakers to gradually shift from general mass production towards mass customization.

The coming time is going to going to be big for the 3D printing business within the automotive sector. Maybe, next time you go to buy a car, you witness it being customized as per your recommendations! Exciting, isn’t it?