Blogs

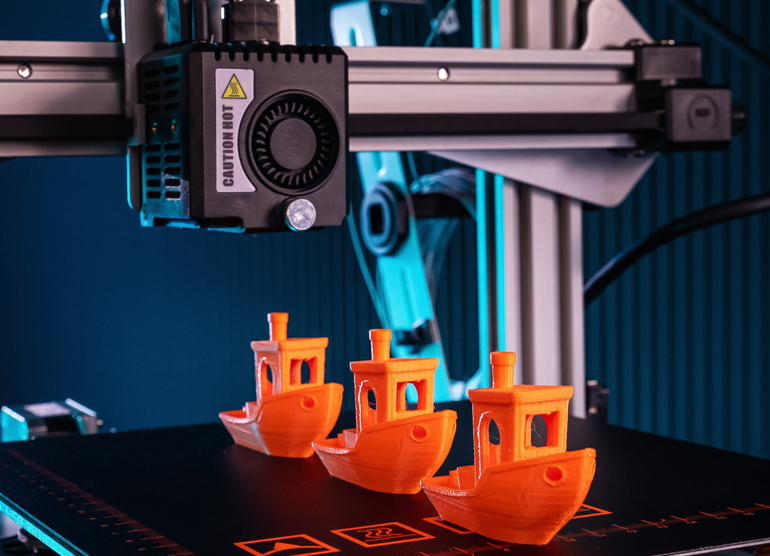

The uncertainties surrounding the world fuel and production prices, the past three years have been difficult for manufacturing industries worldwide, and it appears that this trend will continue into 2023. Despite these difficulties, 3-D printing or additive manufacturing (AM) has been a key factor in assisting businesses in overcoming supply chain disruptions and producing finished goods that are stronger, lighter, and redesigned to have fewer parts.

3D printing is rapidly progressing into a competent production technique. For small and medium-sized production runs, it provides significant advantages and is helpful for rapid prototypes. Let us see how the technology will get there and how much will 3D printing affect the manufacturing and supply chain further in 2023. Here are the major predictions for additive manufacturing in the near future.

3D printing will get more efficient, quicker, and less expensive.

Technologies for 3D printing are evolving expeditiously. The variety and available options will continue to expand as a result of the increasing need for specialized materials that can meet the specifications of final products. The potential to handle a wide range of innovative materials will be essential for the next generation of printers, particularly industrial-grade solutions. This enables businesses to benefit from additive manufacturing in regions where they previously cannot be used.

Even though machine costs are still high, higher printing speeds are driving down the cost of parts. These innovations will accelerate as businesses will start using 3D printing. The versatility of 3D printing is expanding with the inclusion of procedures like dual extrusion. Consequently, more and more industries are adopting 3D printing. Printing without support structures is another discovery that is anticipated to have a substantial impact because it increases the potential uses of additive manufacturing. Also, there is substantial potential for cost and time savings.

An integrated supply chain will include additive manufacturing.

Manufacturers require a wide range of printers, materials, and, most importantly, contacts with other field professionals to maximize benefits. Furthermore, interoperability among different systems is becoming increasingly crucial to harness the potential of 3D printing. Automation in production and post-processing, as well as integrated usability, will be key aspects in the future. As part of a comprehensive and secure platform that integrates all the different phases into one procedure, from concept through materials, digital inventory, production, and delivery, additive manufacturing can offer a completely new supply chain method. Services providing a completely automated, secure platform will be crucial as manufacturers work toward Industry 5.0.

A partnership is essential.

Partnerships can result in synergies and benefits for both parties, resulting in a better product for customers. This has shown to be a key facilitator of industrial production scale in 3D printing. However, more comprehensive collaboration is required to advance. It is necessary to establish standards and ensure interoperability between printer and post-processing systems. Furthermore, sharing production data can lead to better printers and materials for everyone. The optimal solution can only be attained through strong interactions. The next step in creating a better service is to create an ecosystem where service providers, material suppliers, and print farms are interconnected globally.

Boosting supply chain resilience with 3D printing.

Many supply chain interruptions have been addressed in the past using 3D printing. The importance of additive manufacturing in resolving these issues will only grow as technology advances. Manufacturing industries using 3D printing technology may create supply chains that are shorter, stronger, and more resilient because production can be located closer to where the consumer is. Any supply chain has a weak bond which is the physical inventory. However, inventory becomes digital when there is on-demand printing.

Whether the consumer will be receiving the finished product or the producer will be receiving the component, engineers, and manufacturers can send the design file to the 3D printer nearest to the next phase in the supply chain. The need to keep and gradually shift inventory is thereby reduced. Instead, parts can be printed and sent to the nearest distance, lowering CO2 emissions and increasing supply chain resilience.

Sustainable development will advance with additive manufacturing.

Sustainable manufacturing and supply chains are becoming more and more important due to end- user demands, legal requirements, and even moral obligations. This pattern is also seen in 3D printing, which can cut down on production-related waste. Engineers can significantly reduce the weight of the finished part and, as a result, the amount of material required for manufacture by designing a part, particularly for 3D printing. Additionally, 3D printing can decrease the number of parts in inventory and the waste that goes along with it when it is used in a decentralized, on-demand digital warehouse. Likewise, carbon dioxide emissions from transportation are decreased by situating production close to the following stage of the supply chain. Furthermore, the use of sustainable 3D printing materials such as recycled, reused, and biodegradable plastics will increase.

Summing up

As additive manufacturing gains more traction in the marketplace, both big and small manufacturers will have more opportunities to compete. On a wider industrial scale, the benefits of additive manufacturing will begin to be understood. These benefits have been promised and achieved by smaller manufacturers for years.

According to CONTEXT, sales of 3D printing materials, hardware, and services will increase from $12 billion in 2021 to an estimated $38 billion by 2026. This market has been seeing rapid expansion, which is anticipated to continue. Metal 3d printing services in India will open up new possibilities for Rapid prototyping services in India, functional part manufacturing, conformal cooling tooling, and other applications.

Innovae3D is a leading manufacturing company offering 3D printing services in Pune. From design, development, and analysis to printing and post-processing, Innovae3D provides 3D Printing Services in India. Implementing the most recent 3D printing technologies will improve your workflows and increase your ROI.

With the Best 3D Printing Services in Pune, you can turn your concepts into reality.