Blogs

The automotive industry has developed innovations and technologies continuously since its beginning. The major technological advancements in the automotive industry are closely related to improvements in production. Many industrial advancements in the sector are driven by CNC machining.

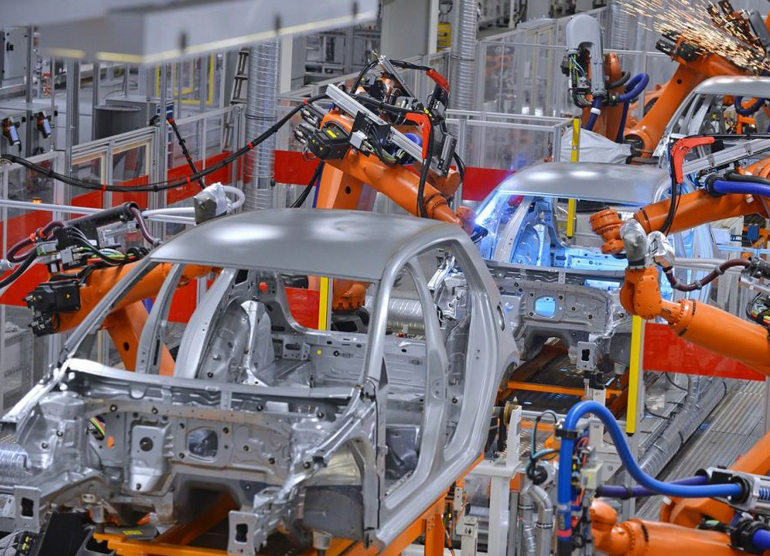

Design, robotics, and production methods have advanced in recent years. The automation of automobile machining significantly increased as a result of all of these. The design and functionality of vehicles have improved due to these similar technologies. The use of CNC machining is widespread. However, this technology plays multiple important roles in the transformation of automobile manufacturing.

Precision CNC machining is essential to the manufacturing and prototype of automotive parts. As part of the prototyping process, manufacturers can construct prototypes to see what the final design will look like and to find and correct any design flaws. Producers can follow the design requirements while avoiding flaws affecting how well those parts function.

If we get back to direct manufacturing, CNC machining is an important tool for the actual production or manufacturing of automotive components. Precision CNC machining has been more prevalent recently in the automotive industry, and its benefits are sought after by automotive manufacturers worldwide.

Benefits of CNC machining in the Automobile Industry

High Speed

The relevance of CNC machining in the automotive industry is greatly influenced by its speed. Machine operations can be accomplished quickly and with little human intervention since computer instructions direct them. It reduces limitations imposed by human nature, such as fatigue, for companies seeking to produce large quantities of automotive parts.

Compared to conventional machining, CNC Machining provides rapid production times for medium- to high-volume production. This is because of its automated nature, which eliminates the need for labor- and time-intensive human milling. Some phases of the production planning process assist in accelerating and optimizing the machine's runtime.

Precision and accuracy

For complex car part designs, tight tolerances are required. The possibility of human error is eliminated because the designs for auto parts produced by CNC machines are precise and capable of creating even the most complex part designs.

Auto parts made to order

Precision CNC machining can produce exact tolerances and do it as often as necessary for automotive products. This is a reliable method, especially for automotive applications, which can maintain the required tolerances for the engine and other components.

Repeatability

A batch of identical auto parts in large quantities is produced using CNC machinery for the same make and model of cars. The fact that automobile CNC machining is a transformative process carried under computer control further ensures its repeatability. This element must be present for any industrial-grade manufacturing setting to operate correctly. It is crucial to ensure consistency between parts batches in the automotive industry. All CNC vehicles made in this way will adhere to the same uniform specifications.

Promotes Automation

Precision CNC machining offers several advantages, including automation. It significantly minimizes the amount of manual labor required to make hardware. Additionally, compared to manual procedures, it enables shorter manufacturing times. If you submit a part to be made on a CNC machine, robotic arms could assist in removing the part once it is finished. In reality, using a CNC machine for manufacturing hardware still involves automation. As a result, employees have more time to concentrate on planning and developing new technological achievements.

Customization of auto parts

Customization of auto parts is possible that need to be restored or are essential components but are no longer manufactured by their manufacturer. Precision CNC machining is used in the automotive sector to produce one-of-a-kind parts. This benefit comes with short lead times, whether one-offs or low manufacturing volumes.

Cost savings

Even though no machine is 100% efficient, the cutting-edge efficiency of a well-made and maintained CNC machine results in cost savings for many companies using it. CNC machining is an excellent prototyping method. It's fast, accurate, and flexible because it can work with any solid material.

Innovae3D CNC machining services in India

Innovae3D offers a wide range of precision CNC machining services in India, including milling, turning, EDM, wire EDM, and surface grinding. With in-house Metal 3D printing capabilities, precise 3-, 4-, and 5-axis CNC machining services, and our skilled team, Innovae3D is a one-stop shop for all your prototyping needs.

To explore more about our Rapid Prototyping Services, Direct metal laser sintering, 3D Printing Services in India, and Conformal Cooling tooling services in India, please contact us.

Let’s start working on your next project. Get a quick quote today.

Reach us: sales@innovae3d.com | Call: +91 76667 15911